Purpose of the flight and payload description

HASP stands for High Altitude Student Platform and is a program aimed to foster student excitement in an aerospace career path and to help address workforce development issues in this area. In the framework of the program a multi-instrumented platform was designed to carry up to twelve student payloads to an altitude of about 36 kilometers with flight durations of 15 to 20 hours using a small volume, zero pressure balloon. The payloads carried by HASP are designed and built by students and are used to flight-test compact satellites or prototypes and to fly other small experiments. The state of Louisiana and the Louisiana Space Consortium have funded the construction and operation of HASP and the Columbia Scientific Balloon Facility (CSBF) through the NASA Balloon Program Office has committed to flying HASP once a year for three years.

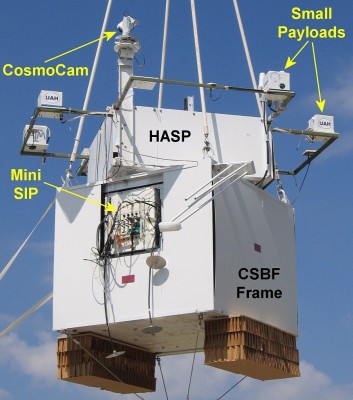

At left can be seen an image of the entire HASP flight configuration payload which is composed of two major components; the CSBF frame on the bottom and the HASP system on the top. The CSBF frame is the primary structural element of the payload and was recycled from an older test payload frame by the CSBF. This component houses all the subsystems CSBF requires to monitor and control the balloon vehicle. On the top corners of this frame are the attachment points for cabling leading to the swivel, flight train, parachute and balloon. Each suspension cable is threaded through a PVC pipe increasing the rigidity of the suspension system and reducing the probability that, upon landing, the swivel would impact student payloads located on the top of HASP. On the bottom of the CSBF frame is the cardboard honeycomb crush pad and attach points for the ballast hopper suspension cables.

The interior of the frame supports a Mini-SIP (Support Instrument Package) that interfaces to the HASP electronics and provides uplinkdownlink communication with the balloon payload, with empty room for a variety of prototypes and test articles, allowing the CSBF to test fly new technology that may improve the performance of future professional scientific balloon systems.

Attached to the core structural frame are four fiberglass frames that support the small (< 1 kg) student payloads. Each brace

extends 56 cm away from the aluminum frame and supports two student payload mounting plates, each of which includes standard mechanical, power and serial communication interfaces. One such brace is attached to each side of the core structure to accommodate up to eight student payloads. This configuration was chosen to minimize interference between the metal frame and any student payloads that may exercise their transmitters during flight. In addition, up to four large (< 10 kg) student payloads can be mounted on the top of the core structure and have a power and communication interface similar to that of the small payloads.

The command and control subsystem, provides the means for receiving and processing uplinked commands, acquiring and archiving the payload data, downlinking status information and interfacing with the student payloads. There are three primary control modules in the subsystem that communicate with each other over a 100 Mbps (megabit per second) internal Ethernet network. These modules are the Flight Control Unit (FCU) which "manages" the subsystem; decoding commands received from the CSBF supplied Mini-SIP and distributing them, watching for units that may need to be reset, collecting status information and downlinking data through the Mini-SIP. In addition, the FCU also monitors the voltages and currents of the power system and collects environmental temperature information for housekeeping records.

The Data Archive Unit (DAU) that controls the on-board recording of all data, making these data records available to other processes on the network, controlling the HASP GPS receiver and managing the time-stamping of all records. All on-board recording is to Compact Flash cards which appear as hard disks to the operating system, but function well in hard vacuum. The Serial Communications Unit (SCU) runs the software which communicates with the student payloads. Without this unit, student data will not be collected.

Finally, temperature sensors are placed at strategic locations around HASP (e.g. batteries, solar shield panels, exterior) to monitor the environment and assess the thermal performance of the system. The input power source for HASP is about 30 VDC and is provided by either a Lambda ZUP36-24 for ground operations or eight B7901-11 eleven cell lithium sulphur dioxide batteries for flight.

One of the major innovations incorporated into HASP was to mount all the command and control components on a single 109 cm x 36 cm Electronics Mounting Plate (EMP). This has the primary advantage that the EMP can be easily removed from the HASP frame for easy access to all the electronics during debugging, testing and/or servicing. In addition, a complete flight spare EMP was built during HASP development and can be used as a "plug and play" replacement in the field should problems arise with the original.

Details of the balloon flight

Balloon launched on: 9/4/2018 at 14:03 utc

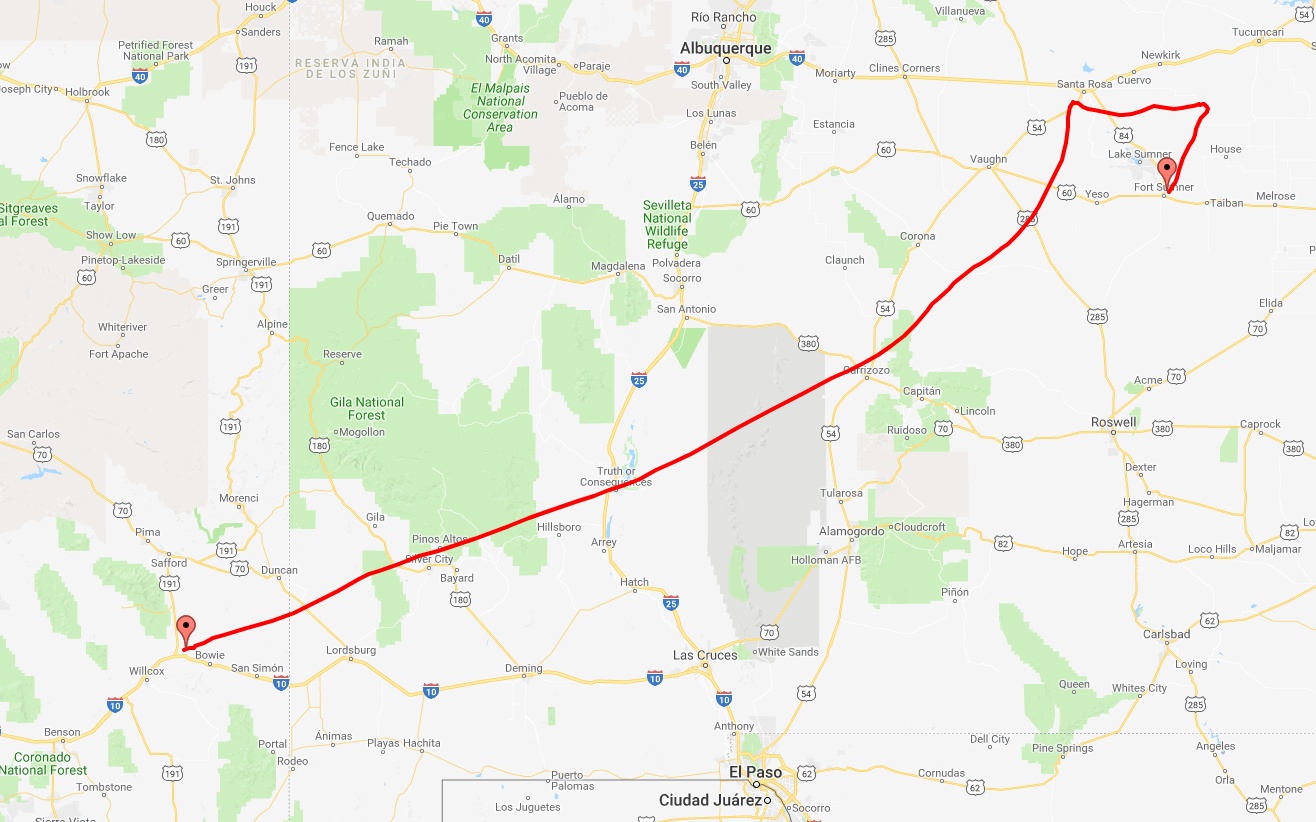

Launch site: Scientific Flight Balloon Facility, Fort Sumner, (NM), US

Balloon launched by: Columbia Scientific Balloon Facility (CSBF)

Balloon manufacturer/size/composition: Zero Pressure Balloon Raven - W11.82-1E-37 - 11.820.000 cuft

Flight identification number: 688N

End of flight (L for landing time, W for last contact, otherwise termination time): 9/4/2018 at 1:32 utc

Balloon flight duration (F: time at float only, otherwise total flight time in d:days / h:hours or m:minutes - ): 11 h 30 m

Landing site: NW of Bowie, Arizona, US

External references

- HASP website Louisiana Space Consortium

- ARC team worked at NASA facility for near space project The American River current, American River College Magazine

- SunbYte: an autonomous pointing framework for low-cost robotic solar telescopes on high altitude balloons Exp Astron 57, 27 (2024)

If you consider this website interesting or useful, you can help me to keep it up and running with a small donation to cover the operational costs. Just the equivalent of the price of a cup of coffee helps a lot.