Purpose of the flight and payload description

This flight was part of the Joint Indo-U.S. Balloon Flight Program - 1961 a cooperative scientific launch campaign carried out between February and April 1961 by scientists from India and the United States in Hyderabad, India. The objective of the extended series of high-altitude balloon flights was to probe the tropical stratosphere using a wide variety of scientific instruments.

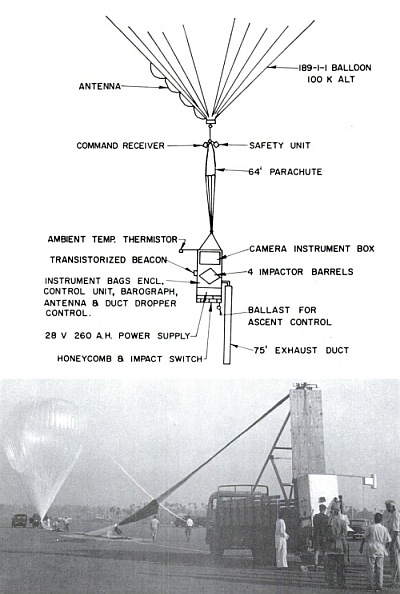

This particular flight was part of a series to mesure the vertical distribution of submicron particles in the stratosphere over India by means of a balloon-borne inertial impactor device known as the AFCRL Large Impactor which was basically a scaled-up version of the impactor air sampler developed by General Mills for the Air Force Cambridge Research Lab. modified by the addition of a backup filter. At left we can see an scheme of the flight train along with an image of the impactor at launch (click to enlarge).

The air-sampling apparatus consisted essentially of a motor-driven rotary air pump which drawed air through a series of jet impactors, thereby removing the solid particles from the air stream. In the large unit, four separate barrels were manifolded to the one pumping system and individually programmed during the ascent to provide a four-point vertical profile on a single balloon flight. Each barrel had a two-stage impactor and a third-stage polystyrene microfiber filter as a backup collector for the very small particles. The four sets of impactor jets for each altitude interval were individually designed and adjusted so that their first and second stages had a 50 percent collection efficiency at about 0.15 microns and 0.02 microns particle radius, respectively, for particles of 2 g/cm3 density, at mid-altitude for the sampling interval. These cutoffs were kept fairly uniform regardless of altitude by increasing the jet dimensions with altitude to compensate for the decrease in air density. A separate battery pack of silver peroxide-zinc cells supplieed electrical power to the various components of the air sampler.

The population of particles was determined after the flight by visually counting the particles under a microscope, and the numerical concentration was then known from the accurately measured volume of air sampled.

A series of four identical flights were performed during the India campaign with the following profile: ascent to 100,000 ft altitude, at or near a 500 fpm rate of rise; air sampling programmed to collect four samples during ascent from 30.000 to 50.000 ft, 50.000 to 70.000 ft, 70.000 to 90.000 ft, and 90.000 to 100.000 ft. The total time flight duration was 150 min from initiation at 30,000 ft. to the descent in parachute.

Details of the balloon flight

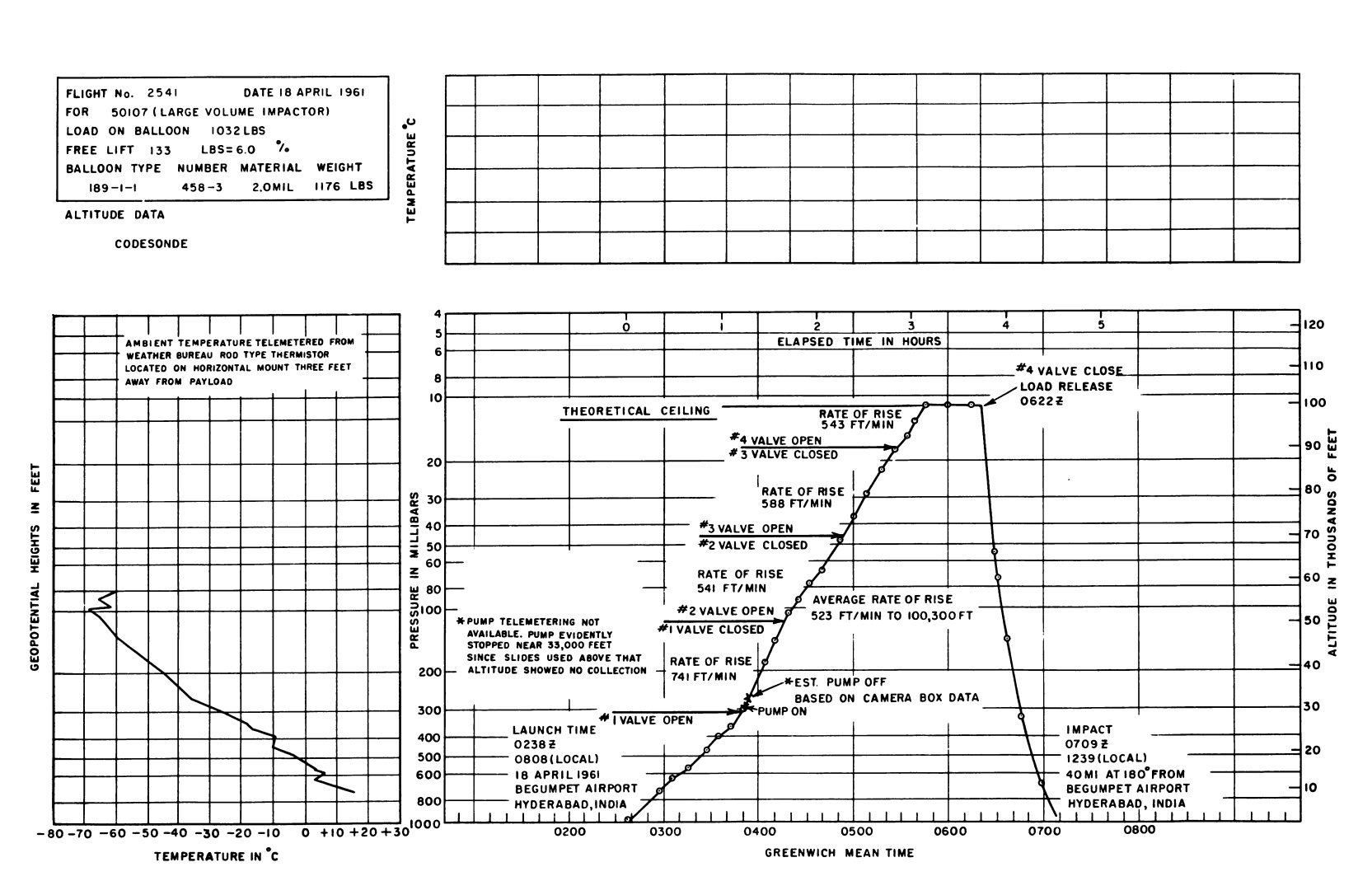

Balloon launched on: 4/18/1961 at 2:38 utc

Launch site: Begumpet Airport, Secunderabad, India

Balloon launched by: General Mills Inc.

Balloon manufacturer/size/composition: Zero Pressure Balloon General Mills 189-1-1 (2.0 mil)

Balloon serial number: 458-3

Flight identification number: GMI Nº 2541

End of flight (L for landing time, W for last contact, otherwise termination time): 4/18/1961 at 7:09 utc (L)

Balloon flight duration (F: time at float only, otherwise total flight time in d:days / h:hours or m:minutes - ): 4 h 31 m

Landing site: 40 Miles S of Hyderabad, India

Balloon was launched on April 18, 1961 at 8:08 local time from Begumpet Airport, near Secunderabad using dynamic method. Rate of rise to 100.300 ft was 523 fpm. Telemetered tropopause temperature was -69°C at 54,000 ft. Once again rpm telemetering was not obtained. It was therefore not known whether the motor and pump were operating during the course of the flight. The system floated at 100.300 ft for a normal duration of 30 min, after which the flight was terminated. Impact occurred 40 miles south from the launch site.

Post-flight examination of the impactor slides showed that the pump had not functioned above 50,000 ft, since the slide from Sampler No. 1 was the only one showing a collection. The flight was therefore unsuccessful. Examination of the impactor unit showed that the heavy duty relay between the power supply and the 3-hp motor was the source of trouble. The ground lug on the relay had worked loose, undoubtedly because of vibration from the pump and motor. This opened the circuit and therefore stopped the pump and motor.

External references

- Joint Indo-United States Balloon Flight Program - 1961 Scientific Report - Air Force Cambridge Research Laboratories (U.S.) - 1962

If you consider this website interesting or useful, you can help me to keep it up and running with a small donation to cover the operational costs. Just the equivalent of the price of a cup of coffee helps a lot.