Purpose of the flight and payload description

This flight was part of a balloon expedition to study cosmic rays in the vicinity of the equator during the International Quiet Sun Year (IQSY) organized and managed by the National Center for Atmospheric Research as a joint United States - India activity. The program was conducted in Hyderabad, India during the late winter and early spring of 1965.

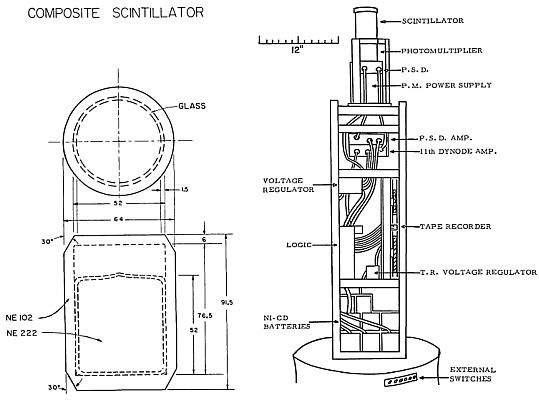

The main instrument on this flight was a fast neutron detector aimed to measure 1-10 Mev recoil-proton and heavily ionizing events produced by neutrons in an organic scintillator. The detector itself is a 5 cm x 5 cm cylindrical volume of organic liquid phosphor, which is surrounded by a 6 mm minimum thickness of plastic scintillator which acts as an anticoincidence shield for charged particles. The composite detector is viewed by a single 5 cm photomultiplier. The set is shown in the far left scheme.

Events produced in the composite scintilator by radiation other than neutrons (like protons and electrons produced by background radiation and gamma rays) are rejected by the detector electronics on the basis of pulse shape. The pulses produced by scintillations of recoil-protons between 1 and 10 MeV are amplified, gated as neutron events and sorted in a seven-channel pulse height analyzer. The seven channels of pulse height information are binary coded and recorded on three tracks of a four track magnetic tape recorder. The fourth track contains a time signal as well as a record of all events produced in the scintillator with a light output greater than that of 1 MeV proton. Ambient pressure, the temperature of the gondola, and time are registered by a photobarograph which also acts as a backup system for the tape recorder, registering the counts in neutron channels 1-5 and 4-7 and in total events.

The instrumented rack (shown in the far right scheme) was designed so that the mass distributed in the balloon gondola would subtend a minimal solid angle at the scintillator. This was to prevent background neutrons produced by high energy radiation in the local material, from reaching the detector. An exterior container housed the photobarograph and the batteries for the heaters in the gondola. Such heaters were required only during night flights, since the insulation, made of 10 cm of polyurethane foam, and the reflectivity of the yellow fiberglas gondola were sufficient to maintain the inside temperature.

Also was part of the flight a X-RAY Counter developed by the University of California aimed to measure atmospheric gamma ray as a continuation of an already performed measurement campaign carried out in Minneapolis and in New Mexico, thus completing a three-point latitude survey. Also using the low gamma ray background near the equator the scientists examined the quiet sun for X-ray emission in the 10 to 100 kev region.

Details of the balloon flight

Balloon launched on: 3/6/1965

Launch site: Osmania University Campus, Hyderabad, India

Balloon launched by: Raven Industries Inc.

Balloon manufacturer/size/composition: Zero Pressure Balloon Winzen 2.940.000 cuft (0.7 Mil. Stratofilm)

End of flight (L for landing time, W for last contact, otherwise termination time): 3/6/1965

Landing site: Ground Abort. Termination squibs fired before launch.

Campaign: No Data IQSY-EQEX

Payload weight: 327 lbs

The flight train configuration was assembled around New York University's neutron counter since it constituted the largest single package. The balloon control instrumentation was positioned on one side as far away as possible from the counter to prevent interference or possible shift in its calibration. The X-ray counter from the University of California was positioned on the other side at a sufficient distance to keep its 30 half-cone angle from being obscured. The New York University barograph was placed in the space between the neutron counter and x-ray counter. A crush pad was placed between the balloon control instruments and the neutron counter. Ballast containers were positioned on opposite ends to preclude any shift in calibration or balance as ballast was expended. Two layers of crush pad were placed beneath the payload. The entire payload was suspended under a 32-ft diameter parachute for descent. Balloon layout and inflation were completed in 45 min.

During removal of the protective sleeve, several large holes were found in the balloon. The holes were caused by the nylon filament tape attached to the protective wrapper. The holes were repaired with 2-in. polyethylene tape with extra polyethylene for back facing. While final preparations were being made for the launch, the termination squibs detonated. The load line at the top of the parachute was severed, allowing the balloon to ascend through the launch spool.

The scientific package was not moved during the mishap. Immediate investigation of the balloon control instrumentation was performed on the launch field. The malfunction was traced to the timer. The timer motors were observed operating counter-clockwise due to reversed polarity. The actuating cam, which holds the termination switch open for a maximum of 100 min, was moving in the opposite direction, and closed the circuit about 8 min after being energized. This same payload was flown the following day.

External references

- Ballooning Support for Cosmic-Ray Experiments NCAR Technical Note NCAR/TN-20, September 1966

8935If you consider this website interesting or useful, you can help me to keep it up and running with a small donation to cover the operational costs. Just the equivalent of the price of a cup of coffee helps a lot.